Product

Product Categories

Filter by price

AngelBlade CAM Pro Nesting Software

Array$0.00

2、CUT Nesting cutting module

3、TEST NC code simulation module

AngelBlade CAM Pro Nesting Software

AngelBlade CAM Pro Nesting Software Introduction

AngelBlade CAM Pro Nesting software was R&D in 2008, which can be used for plasma cutters,flame, plasma, laser, waterjet cutting machines’ Cutting program edition.

AngelBlade CAM Pro Nesting software supports more than 100 types of cutting codes, like Hypertherm, Messer, Esab, Koike, etc. over 100,000 sets of AngelBlade CAM have been used in the market.

Refer to world famous Nesting software, AngelBlade CAM Pro designed its function and operation for reaching a better user-effective experience.

At the same time, AngelBlade CAM Pro can save more cost for users!

AngelBlade CAM Pro Nesting software was made up of sui generis 3 functional modules:

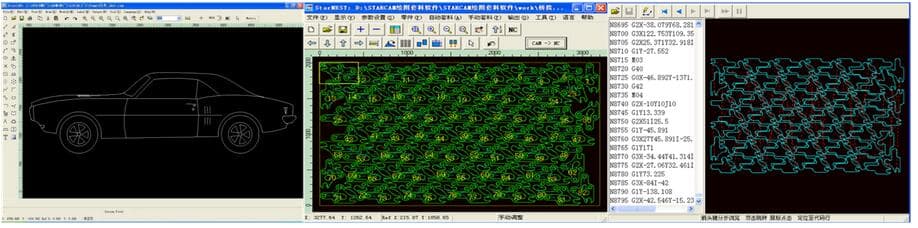

1、CAD Drawing cutting module

2、CUT Nesting cutting module

3、TEST NC code simulation module

AngelBlade CAM Pro Cutting Software

AngelBlade CAM Pro Nesting Software Introduction CAD Main Functions & Feature

AngelBlade CAM Pro Nesting software CAD drawing module can finish the work of nesting parts shape drawing, editing, and support the cutting parts size scaling, copying, arraying, rotating, mirroring etc operation.

AngelBlade CAM Pro supports other formats CAD drawing files (e.g. CAM, DXF, DWG, IGES) import editorial and export operation;

AngelBlade CAM Pro can optimize drawing;

AngelBlade CAM Pro supports users’ parts drawing storage management;

AngelBlade CAM Pro supports processing setting to satisfy different processing requires;

AngelBlade CAM Pro can create parts process NC code.

CAD Drawing Nesting Module Functions

· Parts Plotting Function:

According to the characteristics of cutting parts, AngelBlade CAM Pro nesting software can draw parts plotting function, and easy for operation.

· Scale Display Function:

On the window of drawing, the scale will display, this scale can switch between metric system and British system.

· Control Points Catching Function:

Convenience customers to catch control points.

· Drawing Management Function:

Support processing coverage, marking coverage setting.

· Module Operating Function:

Support user defined modules, modules rotating, mirroring, copying, moving, arraying etc editing operation.

· Drawing Storage Management Function:

Support users drawing storage management, users can classify their usual parts in user parts storage to easy manage and nest processing parts.

· Processing Path Parameter Setting Function:

Freely auto processing patch setting window, easy for processing patch building.

· Drawing File Switch Function:

Support the 3rd parts drawing import and export operation.

AngelBlade CAM Pro Nesting Software

AngelBlade CAM Pro Nesting Software Introduction CUT Main Functions & Feature

AngelBlade CAM Pro nesting module can mass nesting for multiple parts on rectangle plates or remainder plates.

Support short line cutting continually, auto co-edge, and bridging technology.

This module function can reduce a lot piercing times to improve plates using ratio, and raise cutting speed efficiency.

Support manual nesting and auto nesting.

Support multiple plates and remainders nesting.

Support optimizing cutting management.

Quick create multiple CNC codes for all kinds of CNC cutting equipments.

High speed and more effective.

CUT Nesting Module Functions

· Drawing Storage Parts Nesting:

It has file parts and storage parts interposition function. Users can drawing parts or user storage parts add into present nesting processing.

· Cutting Program Management Function:

Increase program management function. When save each nesting mission, it will save as user’s program name, and auto create program file. Under this saved file, the mission nesting file, parts file, nesting table file, remainder file, path setting file and CN code are included together. But also it can auto translate other form file (e.g. DWG, DXF, IGES) into CAM file. Easy for user to copy and process on other places.

· Auto Path Creating Function:

Drawing can have auto patch creating function, more clear setting and easier operation.

· Nesting Table Function:

With nesting program, which can be pre-choosing nesting table setting. It can improve the nesting speed and plates using ratio.

· Nesting Table Function:

Improved auto nesting parameters setting function, with kerf setting in auto parameter setting table to satisfy co-edge cutting and kerf make-up cutting.

<p style="box-si

Reviews

CNC PRODUCTS

Call. +86-10-51662600

Email. info@steeltailor.com

Cannes Industrial Park, No.18 Shuang Qiao Dong Lu, Chao Yang District

Beijing ,China. 100121