Product

Product Categories

Filter by price

Kjellberg CutFire 100i plasma cutters

Array$0.00

high operating efficiency of 92 %

soft-switch-inverter made in Germany with duty cycle of 100 %

dust protection through inbuilt filters

comfortable operation by

Kjellberg Finsterwalde plasma cutter is one of the world's leading manufacturers of high-quality plasma cutting technique for manual and automated applications.

In addition to the well-known HiFocus and FineFocus series plasma cutters, Kjellberg Finsterwalde

offers the air-cooled CutFire 100i for simple cutting applications. This flexible and

powerful inverter power source is ideally suited for cutting thin plates.

Typical applications are in metal construction, in particular in ventilation and

control cabinet construction and in many other handicraft businesses,

production and industrial companies.

Reliable cutting engineering

The new inverter power source CutFire 100i air plasma cutter, which is provided with the latest

primary switched power electronic and controls, is characterized by

- high reliability and power potential (up to max. 100 A)

- high operating efficiency of 92 %

- soft-switch-inverter made in Germany with duty cycle of 100 %

- dust protection through inbuilt filters

- comfortable operation by

clearly arranged control panel

current pre-adjustment for optimum

operation, large digital display

easy pressure adjustment and monitoring

LED-display for process monitoring

remote control for cutting preparation

Arc voltage depending height control and torch guiding system

A safe plasma process and a high cutting quality can be achieved only, if the

torch distance to the workpiece surface always is constant, and if the torch

is lifted up when piercing starts.

The arc voltage depending height control KHC 1 ensures process stability and

constant good cutting quality, and furthermore it offers a number of cost-

saving effects (increase of lifetime of consumables, material saving by better

plate utilization, accuracy of the cut, collision protection, etc.).

The torch guiding system FE 1 is suitable for straight and circle cutting.

Air-cooled torch technique

The inverter delivers good cutting quality and high productivity for a wide range of

thicknesses and various metallic materials, including galvanized steel plates. The

plasma machine torch Flash 100 ensures cost-saving and reliable operation by:

- using the low-price plasma gas Air

- lowest cost of consumables

- low air consumption for plasma gas and cooling

- accurate high-voltage ignition and piercing properties

- plasma torch with central connector ensures quick torch change

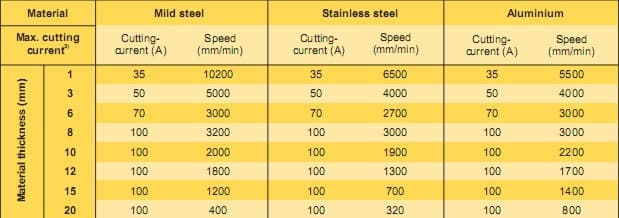

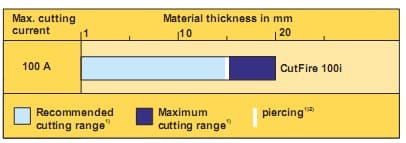

Range of applications

1) These data are depending on the materials to be cut and their compositions

2) Piercing capability is dependent on material, thickness as well as performance

of THC and CNC.

Control and display elements

- Signal lamp, yellow "error"

- Signal lamp, white "plasma torch ON“

- Pressure regulator "plasma gas“

- Pressure gauge "plasma gas"

- Digital display "cutting current“

- Tumbler switch "gas purge / torch operation"

- Potentiometer "cutting current", stepless

- Emergency stop

- Illuminated button, green ,stand-by“

- Key switch "mains ON

Operating Data:

3) Listed cutting speeds are depending on material characteristics, gas parameter,

guiding system as well as proper consumables. According to quality requirements

cutting speeds may differ.

http://steeltailor.com/for_sale/index/id/kjellberg_cutfire-100i_steeltailor.html

Reviews

CNC PRODUCTS

Call. +86-10-51662600

Email. info@steeltailor.com

Cannes Industrial Park, No.18 Shuang Qiao Dong Lu, Chao Yang District

Beijing ,China. 100121